VPEQ

DEPLOCEX

Equalization of the frequency response

in compression drivers

Any channel through which a sound is transmitted has its eigenmodes. If we think in an analogy with the transmission of plane wave inside a tube closed by a diaphragm and open in the other end the modes can be easily calculated, although the problem is much more complex in the case of the compression driver ducts . Those modes will result in valleys and peaks that worsen the frequency response.

Our R&D team after much thought and extensive research, simulations and tests to improve the frequency response of our compression drivers has come up with this unique solution.

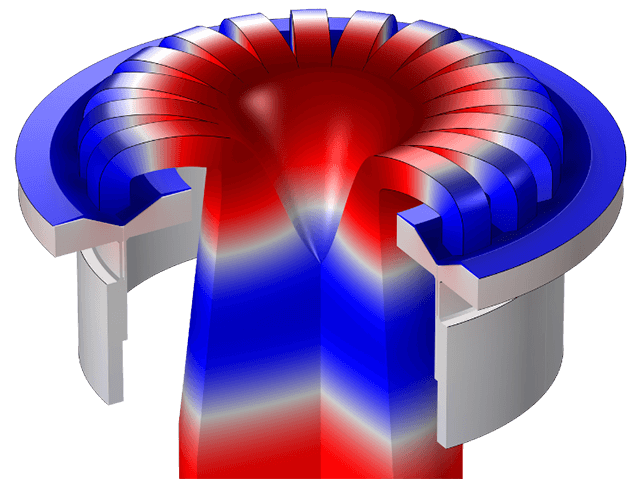

The working principle to solve this complex problem is quite simple. Through the variation of the duct shape, it is possible to linearize the response of the system and obtain a better transfer function.

Variations in the tube in width and a sort of organic

shape designed according to different mathematical functions will create a notable variation of the sound pressure level for the calculated frequencies resulting in a much better transient response.

Improved thermal dissipation

for compression drivers

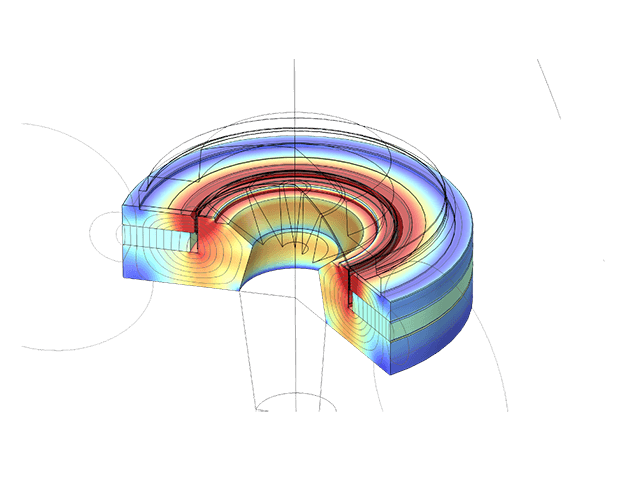

In a sector in which high performance is of great importance, when designing the coil configuration, the one layer edgewound wire or the double layer round wire coils are traditionally used to obtain the necessary Bl if the high SPL required in the industry is to be achieved.

This technique, in the case of the double layer configuration has the drawback that one of the coil layers is not capable of dissipating as much heat as the other. And normally the flat wire configuration features a short magnetic gap. Therefore, power handling is limited and power compression due to high temperatures makes its appearance with much less voltage.

Through DEPLOCEX, the surface of the coil and the magnetic gap is maximized, deploying the coil in a configuration to increase the heat dissipation through radiation, while maintaining the same Bl and final SPL. The thermal transmission of the entire length of the coil with the iron is higher.

The coil temperature is reduced by 30% which minimizes the effect of power compression and achieves high frequency drivers more than 15% more powerful.